Defining Machine Learning

Machine learning (ML) may have a rather different explanations, depending on whom you ask and where you look for. Following are the four practical definitions from reputable sources:

“Machine learning is the science of getting computers to act without being explicitly programmed.” – Standford University, Arthur Samuel, Machine learning pioneer

“Machine learning algorithms can figure out how to perform important tasks by generalizing from examples.” – University of Washington

“The field of Machine Learning seeks to answer the question. How can we build computer systems that automatically improve with experience, and what are the fundamental laws that govern all learning processes?” – Carnegie Mellon University

“Machine learning is based on algorithms that can learn from data without relying on rules-based programming.” – McKinsey & Co.

Machine Learning in Industry 4.0

Machine Learning supports Engineers to increase the efficiency and helps to reduce the engineering and testing time. This section shows the potential and the advantage while using ML in industrial applications. Furthermore the link between Machine Learning and Industry 4.0 is displayed.

Whats the definition of Machine Learning in Industry Processes and Applications?

“Every manufacturer has the potential to integrate machine learning into their operations and become more competitive by gaining predictive insights into production.” –Forbes

“Machine learning can be used in almost every facet of modern industrial processes, including improvements to product design collaboration and predictive operations.” – industrial-iot.com

According to dzone Industry 4.0 is expected to benefit from ML methodologies in the following manners:

- Smart factories will have a closely monitored, automated production process.

-

Advanced digitized networks will be installed for data collection and transfer.

-

Machines, humans, software systems, and products interact over the internet.

-

Inspections, supervision, modifications, and communication can be automated.

-

This value-added manufacturing process is heterogeneous, decentralized, and flexible.

-

New devices will be embedded to scale up the system and achieve complete automation.

Manufacturing

Machine Learning helps manufacturing facilities predict and prevent future failures before cost impacts or an unexpected machine shutdown occurs. “Machine-learning algorithms bring two major advantages to the production process, improvement of product quality and flexibility of the production process” – datafestival.

The following article 10 Ways ML Is Revolutionizing Manufacturing describe ten ways machine learning is Revolutionizing manufacturing. This article display very clear how machine learning is used in industry applications, mainly in manufacturing. The quality of a product is depends on the quality of the assembled parts.

Another aspect uf using machine learning in industrial operations is,” The ROI of applying machine intelligence to industrial operations”. – Modern Manufacturing: Machines Learning from Machine Learning. This recently post describes ” How AI and Machine-Learning are reshaping the manufacturing“. The world is rapidly moving toward Industry 4.0 or the Fourth Industrial Revolution, where artificial intelligence (AI) and machine-learning based systems are not only changing the ways we interact with information and computers but also revolutionizing the manufacturing sector. – automationmag

Supervised learning

Supervised learning has an input variables (x) and an output variable (Y). An algorithm learns plotting the function from the input to the output.

Y = f(X)

The goal is to find the plotting function so that a new input data (x) can predict the output variables (Y). In Industry this dependent variable is called the predictor or the factor of interest for example., sales forecast, system-performance, specific optimisation parameter, marketing effectiveness etc

Supervised learning problems can be divided into regression and classification problems.

- Classification: A classification problem is when the output variable is a category, such as “high” or “low”, “full” or “empty”, “0” or “1” or “yes” or “no”.

- Regression: A regression problem is when the output variable is a real value, such as “number of produced bottles”, “weight”, “pressure” or “temperature” .

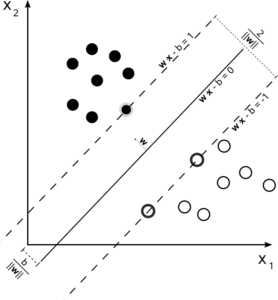

Support Vector Machines

A support vector machine is a complex but powerful classification technique that separates data most cleanly. A classifier divides its input space into two regions, separated by a linear boundary. Here, it has learned to distinguish black and white circles. This method is used for recognizing handwriting, classifying images and to examine the feasibility in forecasting seasonal time series data of production value.

Unsupervised learning

Unsupervised learning has an input variables (X) but not a corresponding output variable. Unsupervised learning problems can be divided into Clustering and Association problems.

- Clustering: A clustering problem discovers the characteristic groupings of data, such as grouping digital image processing for image segmentation.

- Association: An association rule-learning problem discovers rules that describe large portions of data, such as Amazon costumers that buy X also tend to buy Y.

Semi Supervised learning

Semi Supervised learning involves function estimation on labeled and unlabeled data. This approach is motivated by the fact that labeled data is often costly to generate, whereas unlabeled data is generally not.